I

recently purchased a pair of low profile LED ceiling lights from a

charity auction on Ebay.

It seemed like the kind of thing that I’d find a use for

eventually, and it was for a good cause.

After buying I had a message from the seller to tell me that they

only had one driver for the two panels – I went ahead with the

purchase because at the end of the day I wasn’t expecting them to

be new and pristine from a charity auction.

My curiosity was piqued when they arrived. I noticed another label

sticking out from underneath the address label. I peeled it back, and

revealed an Amazon delivery label to a different address.

Initially I figured perhaps it was an Amazon returned item – one

of the drivers was missing, therefore the original purchaser returned

it, and it was sold on to the charity as one of those wholesale

return pallets that you see advertised.

I did also think that the wires on the

mains side of the LED driver seemed a little bit thin. However I

tested it with those panels and they actually seemed to work okay, so

I didn’t think much more of it.

Losing faith

So, I started to put together a

project plan to make a light fitting with them.

I wanted to add in a few extra accent

lights but everything I had was 12v, and the light fittings driver

was 18v. While I was mulling over options – adding in a separate

transformer, the space and heat issues to work round, etc. I noticed

a couple of other things.

The case of the driver seems to have

fake screw heads stamped on them. Not in itself a problem, but kind

of sketchy.

And the panels themselves are stamped

with 18w, not 18v.

The output of the driver says 9-18v at

300ma.

W=V*A.

There’s no way that if those panels

are 18w, the driver can provide enough power to them.

This made me rethink my theory on the

background of these lights.

Having a look on Amazon I can see very

similar products, with identical looking drivers – the only

difference being that the outputs are rated differently.

My guess is that this set of lights

came with incorrect drivers, and the original purchaser damaged one

whilst trying it.

It’s only a theory and not enough to

make a claim against, it ultimately is enough to destroy my faith in

these lights and make me not want to use them as they are.

Rebuilding the electronics

I had built the design around the size

of these panels, so I decided to rip out all of the electronics.

On doing so I realized that the panels

were just flexible LED strip edge mounted to a diffuser.

I swapped out the LED strip that was

there with some white 12v strip LEDs. I had to trim about a

millimeter off the sides of the diffuser in order to account for the

slightly larger LEDs.

In an initial test the LED light was

quite patchy, so I took the diffuser from the second light and

doubled up. This makes a notable difference.

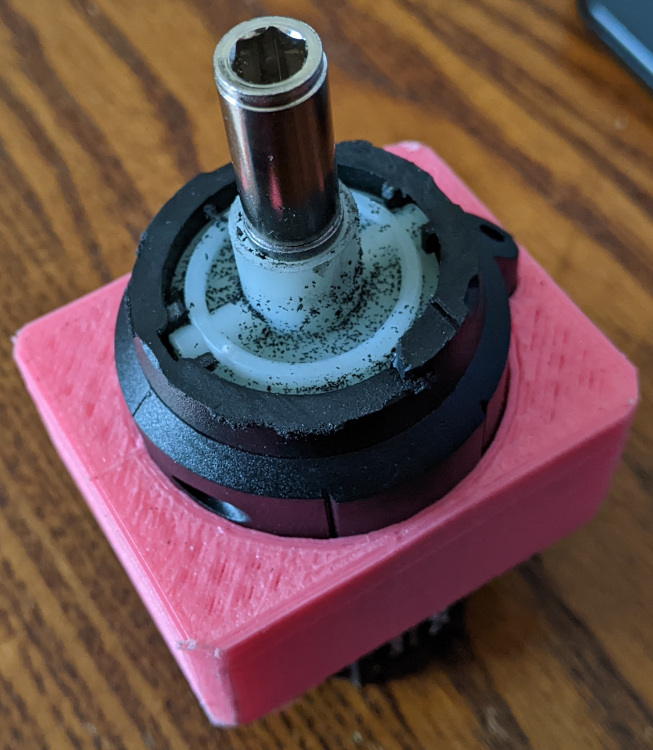

To drive the strip I’m using a

regular RGB LED control box.

Initially my choice of this was simply

because it was available and had a small profile so would fit well in

the fitting.

However this also gave me the idea I

could run the accent lighting and the main light on different color

channels, allowing them to be controlled separately. It would also

allow me to dim the light.

The design

Because I don’t want to carve out my

ceiling to flush fit the panel I planned to build a small mitred

frame, with another frame mounted at forty five degrees behind it.

The back frame would contain some accent lights, with the front frame

housing the main light fitting.

the fitting needed to fit in with the

of our lights in the room, so I disassembled the original fitting and

spray painted it black.

For the wood frame I opted to use

zebrano.

The frames are simple squares with 45

degree mitres, and a 2mm deep by 10mm wide rebate to fit the light

fitting frame flush with the surface.

The back frame was turned at a 45

degree angle, and screwed to the front frame.

The back frame also had a pair of key

hole plate mounted to the back, which will be used for connecting to

the ceiling.

Accent Lighting

Rather than cut up the filters from

the second light, I opted instead to use a stack of filters from an

old PC monitor. It was simply a case of measuring out the triangles,

cutting them and then gluing them in place with hot glue.

Each corner would have a single

segment of white LED strip (3 LEDs per corner). These would be

connected in series and then connected to the RGB LED control box, on

a different color channel to the main light, allowing them to be used

independently.

The rest of the electronics

The IR receiver from the control box

sticks out behind the front frame, so it is not visible from ground

level, but catches enough reflected light from the ceiling to

function.

However, this didn't last long and soon found itself wrapped in black tape because what I didn't realise at the time was that the IR receiver worked on the same encoding as our TV remote and we soon bored of having the lights change as we scrolled through TV guide menus.

PSU

The power supply is provided by an

AC-DC “wall-wart” – I had to be quite selective in which one I

picked to fit within the frame. The one I opted for had a removable

face plate which allowed me to remove the socket pins and wire

directly into.

The end result